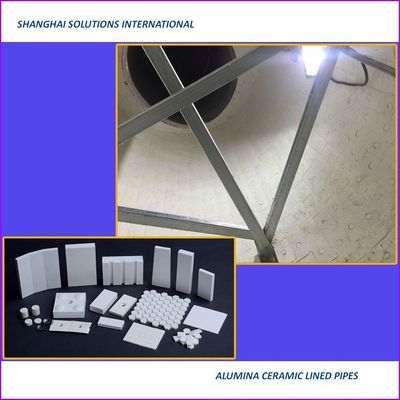

Wear Resistant Alumina Ceramic Lined Pipes with Moulding Processing

Product Details:

| Place of Origin: | Jiangsu, China |

| Brand Name: | SI |

| Model Number: | 200 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 kg |

|---|---|

| Price: | $200.00 - $500.00/pieces |

| Packaging Details: | 1. Standard export carton / Wooden case / Pallet<br>2. Customize according customer's requirements |

| Delivery Time: | Sample needs 5-7 days, and mass production time needs 15 -30 days |

| Payment Terms: | T/T, L/C, MoneyGram, Western Union, Cash |

| Supply Ability: | 1000 Piece/Pieces per Month |

|

Detail Information |

|||

| Type: | Ceramic Parts | Application: | Industrial Ceramic |

|---|---|---|---|

| Material: | Alumina Ceramic | Processing Service: | Cutting, Punching, Moulding |

| Port: | Shanghai | ||

Product Description

Product Description

High alumina ceramic lined Bends, Pipes, Elbows

We supply and install a wide range of purpose made pre-engineered alumina ceramic tiles. Our highly-experieced technical experts can evaluate your application for a pre-engineered tiled solution no matter how complex. Our pre-engineered tiles optimize the lining life and facilitate the best possible lining, even for complex profiles.

High alumina ceramic lined Bends, Pipes, Elbows are reliable, maintaining close manufacturing tolerance, and ready to install and hence facilitate quick replacement and provide long lasting trouble free operations. Ceramic lined equipments consist of ceramic line pipes, ceramic lined elbows, ceramic lined cones, ceramic turrets, ceramic lined hydro cyclones, ceramic lined orifice, and ceramic lined valves. Thus it helps user to get maximum efficiency of the equipment.

With the use of CAD facility and our continuous efforts enable us to design and supply profiles like square to round transitions, splitter and other surfaces which are not common regular geometric shapes.

High alumina ceramic lined Bends, Pipes, Elbows are reliable, maintaining close manufacturing tolerance, and ready to install and hence facilitate quick replacement and provide long lasting trouble free operations. Ceramic lined equipments consist of ceramic line pipes, ceramic lined elbows, ceramic lined cones, ceramic turrets, ceramic lined hydro cyclones, ceramic lined orifice, and ceramic lined valves. Thus it helps user to get maximum efficiency of the equipment.

With the use of CAD facility and our continuous efforts enable us to design and supply profiles like square to round transitions, splitter and other surfaces which are not common regular geometric shapes.

Technical data /Alumina ceramic tile:

|

Item/Product

|

92Series

|

95Series

|

|

Al2O3(﹪)

|

≥92

|

≥95

|

|

Hardness(Mohs)

|

9

|

9

|

|

Water Absorption(%)

|

≤0.02

|

≤0.02

|

|

Fracture toughness(MPa)

|

3.65

|

3.75

|

|

Bending strength(MPa)

|

255

|

275

|

|

Density(g/cm3)

|

≥3.60

|

≥3.65

|

|

Compressive Strength(Mpa)

|

≥850

|

≥900

|

|

Thermal Conductivity(W/m.K)

|

16.8

|

16.8

|

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Company Profie

Our factory was established in 2014, with a total investment of 120 million yuan. We are a Chinese-Japanese joint venture specializing in the production, sales, research and development of Silicon Nitride ceramics.

We adopted the most advanced technology and equipments in the world, and import the first class raw materials from Japan for producing the best quality Industry Ceramics. Now we are one of the biggest manufacture of Industry Ceramics with a yearly output 200 metric tons.

By continuing to innovate and develop in the technologies, we provide a full range of solutions for die casting industry. We have a professional R&D center and a strong after-sales service team. “ Quality best, Credit foremost, and Service first” is our business principle. Welcome friends from all walks of life to visit, guidance and business negotiations.

We adopted the most advanced technology and equipments in the world, and import the first class raw materials from Japan for producing the best quality Industry Ceramics. Now we are one of the biggest manufacture of Industry Ceramics with a yearly output 200 metric tons.

By continuing to innovate and develop in the technologies, we provide a full range of solutions for die casting industry. We have a professional R&D center and a strong after-sales service team. “ Quality best, Credit foremost, and Service first” is our business principle. Welcome friends from all walks of life to visit, guidance and business negotiations.

FAQ

1. Q: Are you a manufacturer or trading company ? A: We are professional manufacturer in China ,and have in this line for more than 15 years. 2. Q: Will your company supply samples? A: Of course,if we have the goods in stock, we will be glad to offer you free samples. 3. Q: Would it be possible for us to visit your factory? A: Sure, you are welcome to visit our factory. 4. Q: Do you support OEM? A: Yes 5 Q: What is your payment terms? A: T/T, LC, Western Union, Money Gram,etc

Want to Know more details about this product